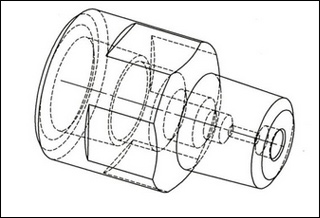

Venturi for steam traps on 'bitumen process' exchangers

One-piece, flangeless, 25-lb wafer-style stainless steel venturi traps like this solved chronic steam trap problems on high-pressure 'bitumen process' heat exchangers.

Designed to fit between 6-in. ANSI 600# flanges, it successfully replaced a 400# float trap which failed regularly causing unacceptable loss of bitumen temperature.

The project at a northern Canadian refinery, involved 790-psi heat exchangers that process bitumen, discharging 69,000-lb/hr condensate. According to the manufacturer, since the 25-lb units were installed in 2008, bitumen temperature has been constant and steam-related visibility and safety problems eliminated. This is critical since hot condensate is recirculated 24 hr/day, instead of being dumped on the ground.

Declared more than an orifice plate, the permanent venturi units are custom-sized for specific applications, including petrochemicals. They are made of extra-hard stainless steel that will not wear.

Installation is said to be simple: Drop the 25-lb unit and gaskets between ANSI 600# flanges - tighten the bolts. Additional custom venturi traps information is free.

Enercon Systems Company

42 Sycamore Lane, # 3178, Woodstock, GA 30188