Enercon Solution

ENERCON SERVICES

- Steam System Technical Reviews

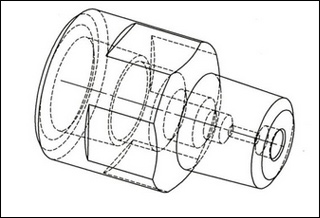

- Enercon Venturi Units: Venturi Technology for Condensate Removal

- Specialized Solution Design and Fabrication

- Steam Trap Surveys

- Offsite Technical Support for Three Years on all Services

TOTAL SOLUTION BENEFITS

Historically, after implementation of our findings from our technical evaluations and our Enercon Venturi Units, Enercon customers typically report the following;- Increased Facility and Equipment Operational Efficiency;

- Improved Product Quality;

- Reduced Water and Chemical Usage;

- Virtual Elimination of Steam Trap Maintenance;

- Reduced Related Equipment Problems such as Low, Inconsistent Temperatures, Pressure Drops, High Back Pressure and Water Hammer, Etc.

See FAQ section for additional information

Contact us about using Enercon Venturi's technology. We proudly serve companies in the United States, Canada, and the U.K.