Venturi Steam Trap Technology

THE KEY TO SYSTEM PERFORMANCE

The key to operational performance in a steam system is the efficient purging of all condensate, while maximizing dry heat that stays in the system. Water in the system reduces heat transfer and causes corrosion, erosion, water hammer, and other problems. The Enercon Venturi Unit's innovative design completely eliminates condensate from a steam operating system while maximizing the system's retention of BTU rich, dry heat.ENERCON'S VENTURI TECHNOLOGY

Venturi technology is an efficient, cost effective and proven method to remove condensate. Enercon has worked with over 1,000 facilities over the past 30+ years, reducing energy consumptions and maintenance costs for those facilities. While cutting energy costs and virtually eliminating steam trap maintenance, our Enercon Venturi Condensate Removal Unit and steam system evaluation services have also resolved problems such as:- High water and chemical usage

- Low and inconsistent temperatures

- Feed and return pressure issues

- Water hammer

HOW A FIXED VENTURI WORKS

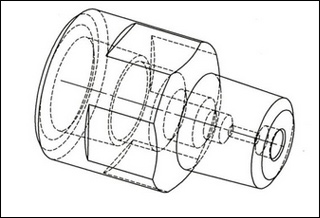

Often overlooked in today's high-tech environment, the steam trap is critical to an efficient steam system. The job of both Enercon's fixed venturi and all steam traps is to efficiently release condensate from the system, which is formed continuously as steam gives up its latent heat. Removing condensate effectively is critical because excess water insulates and reduces heat transfer, can cause equipment damage, water hammer, and reduces the energy-to-pound mass of the steam.A traditional steam trap is designed to open in the presence of condensate and close in the presence of steam. Internal floats, buckets, discs, etc. provide the open/shut mechanism. With Enercon's venturi steam trap, steam traveling at a high velocity forces a much denser condensate through a smaller, precisely sized venturi, effectively blocking steam from escaping. The Enercon unit is sized to handle 100% of the condensate load produced by a particular application. At 100% capacity, an accurately sized venturi loses no steam and backs up no condensate. However, there's a common misperception that when the load drops below 100% capacity, the venturi loses steam. This is not true as it relates to typical steam system operations.

A load can vary significantly according to heat requirement, but that does not mean it varies as it relates to the steam trap. For instance, a drip leg or tracer typically has a fairly constant condensate load and pressure differential, but air process equipment, submerged coils, etc. do not.

A coil with a solenoid valve uses more steam to bring a cold tank up to temperature, but during that period the control is open and the coil is pressurized 100% of the time. Basically, 100% load and 100% flow to the steam trap. When the tank is hot, the control may only be open 25% of the time because the tank only needs 25% of the startup heat to maintain operating temperature. A fixed venturi will be efficient throughout the process. The same is true for equipment using a modulating control. As the heat requirement goes down, the modulating control closes reducing the pressure in the equipment. The result is a lower condensate load and a lower driving pressure. A fixed venturi is also efficient through the entire process.

There are very few properly engineered applications that would not qualify to be converted to a venturi. If Enercon comes across a poorly designed application, we will give the customer the reasoning and the proper design parameters to improve the equipment's efficiency.

Enercon System's oldest conversions, some with 30+ years in service, are still operating efficiently with the original units.

INNOVATIVE TECHNOLOGY FOR A MULTITUDE OF INDUSTRIES

Many of our clients have asked us, "Is there a specific type of industry that the Enercon Venturi Unit is not applicable to?" The answer is NO. The Enercon Venturi Unit is already being used in a variety of industries:- Petrochemical

- Lumber

- Plating

- Chemical

- Pulp & paper

- Packaging

- Pharmaceutical

- Food & beverage

- Hospitals

- Large buildings

- Airports

- Universities

- Dairy industries

- Power generation

- Etc...

Enercon Venturi Units are being used in facilities ranging from small, simple, low-pressure systems to huge, complex, multi pressure, multi- process systems. Clients range from small individual plants to multi operational, multi facilities of Fortune 500 companies.

On completely converted plants, Enercon technology has been applicable for and replaced, on average, 99% of existing conventional traps.

Contact us about using Enercon Venturi Condensate Removal Technology that continuously removes condensate. We proudly serve companies in the United States, Canada, and the United Kingdom.